Automatic High Speed V Bottom Food Paper Bag Making Machine

Specifications

| Name | Specification | Quantity | Unit | Unit Price | Total Amount |

Remark |

| V BOTTOM PAPER BAG MACHINE | 260 | 1 | FOB WENZHOU | |||

| V BOTTOM PAPER BAG MACHINE | 350 | 1 | FOB WENZHOU | |||

| 1.The above quotes exclude tax, no freight, The above quotes exclude tax, no freight,2. The product is guaranteed for 12 months according to national regulations. Products according to the national regulations warranty for 12 months, Products according to the national regulations Warranty for 12 months, the main electrical appliances warranty for 12 months 3. Terms of payment: 50% deposit, 50% payment before delivery. Payment method: 50% deposit, and 50% payment is arranged before delivery. 4. Delivery time: 40 working days after confirmation. Delivery time: 40 working days after confirmation 5. The quotation is valid for 10 days. The quotation is valid for 10 days |

||||||

Sample pictures

Performance and use

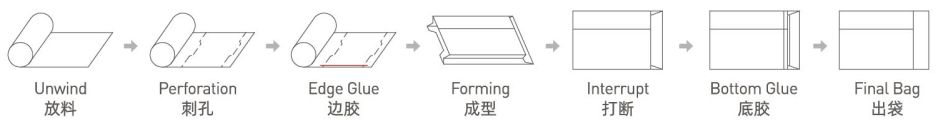

Automatic high-speed paper bag machine by the drum original color paper or printed drum paper such as kraft paper, striped kraft paper, oily paper, food shower film paper, medical paper and other paper roll material bag making process by thorn hole, glue, above, edge formation, interruption, bottom, paste bottom, finished bag output completed.This machine operation is more convenient, more efficient and more stable, is the ideal equipment for the production of various different paper bags, leisure food bags, bread bags, dried fruit bags and other environmentally friendly paper bags.

main feature

1. Easy touch screen human-machine interface, the operation function is clear at a glance, easy to control

2. The original Japanese Mitsubishi sports controller is adopted to ensure the stable high-speed operation through the integration with the optical fiber

3. Japan Mitsubishi servo motor with German Schke color standard eye correction to accurately track the print bag size

4. Hydrhydraulic lifting structure and automatic constant tension control.

5. Brushless servo motor is used for raw material correction to reduce the alignment adjustment time of paper roll.

technical parameters

| Model | WST-JD260 | WST-JD350 | |

| Cutting Length | 120-400mm | 180-630mm | |

| Bag length (L) | 100-380mm | 100-380mm | |

| Bag width(W) | 80-250mm | 100-340mm | |

| Insert size(G) | 20-30mm | 20-90mm | |

| Ladder height | 15mm | 15-20mm | |

| Paper bag speed | 100-600pcs/min | 30-400pcs/min | |

| Paper width | 160-780mm | 220-1000mm | |

| Maximum diameter of paper material | 1000mm | 1000mm | |

| Inner diameter of paper | 76mm | 76mm | |

| Paper thickness | 45-80g/㎡ | 45-80g/㎡ | |

| Working gas | ≧0.12m³/min,0.5-0.8mpa | ≧0.12m³/min,0.5-0.8mpa | |

| Power | 380v 3phase 4line 12kw | 380v 3phase 4line 12kw | |

| Total weight | 3500kg | 4500kg | |

| outline | 6000*1600*1800mm | 9100*1900*1950mm | |

machine configuration

| Control System | |||

| Name | QTY | Original | Brand |

| CPU Program Controller | 1 | Japan | Mitsubishi |

| Human-computer touch screen interface | 1 | China | Flexem |

| Photoelectric eye for printed-bag tracking | 2 | Germany | SICK |

| Japan | Panasonic | ||

| Low voltage electrical apparatus | 4 | France | Schneider |

| Photoelectric sensor | 5 | Japan | Panasonic |

| Pneumatic component | 6 | Sino-foreign joint venture | Noulid |

| Servo Motor | 3 | Japan | Mitsubishi |

| Host server | 1 | Japan | Mitsubishi |

| Traction servo | 1 | Japan | Mitsubishi |

| 1 | Japan | Mitsubishi | |

| 1 | China | Resay | |

| Deviation correction and tension control system | |||

| Name | QTY | Original | Brand |

| EPC controller | 1 | China | Enris |

| Servo motor for EPC | 1 | China | Enris |

| Ultrasonic sensor | 1 | China | Enris |

| Magnetic powder brake | 1 | China | |

| Automatic Tension System of Magnetic Powder | 1 | China | |

| Feeding hydraulic cylinder | 2 | China | |

| Transmission | |||

| Name | Qty | Original | MTED |

| Synchronous belt | 2 | China | |

| Synchronous wheel | 4 | China | |

| Bearing | 213 | Japan | NSK |

| Guide roller | 9 | China | |

| Gear | 23 | China | |

| Glue position | |||

| Name | Qty | Original | MTED |

| Bottom glue (bottom-sealing white latex) | 2 | China | |

| Motor for bottom glue evening | 1 | China | |

| Pneumatic auto glue filling valve | 1 | China | |

| Side glue | 1 | China | |

| Glue Glue Position Detection | 1 | Japan | Panasonic |

| 2 | China | ||

| High-pressure glue barrel for white latex | 1 | China | |

Our service

You can expect satisfactory customer service with long tradition. We are highly devoted to the most optimal solid and liquid separation solutions to meet your specific needs. We have the effective service system to ensure professional and flexible management of any affairs.

1.Pre-sales technical consultation

2.Model selection

3.Machine guidance

4.Operation & maintenance training

5.Maintenance service

6.Quick supply of spare parts

7.Customer satisfaction track

After-sale Service

We promises that all machines made by us come with services of repair and replacement.

Machine warranty is 12 months. We provide free repair services to any failures caused by us within warranty time. However wearing parts are not included.

1.Any quality failure problems happens within guarantee period, we will reply within 4 hours after receiving your request.

2.We will provide lifelong maintenance service to all parts and regular maintenance to flatbed die cutters.

3.We will handle any quality failure occurred within warranty time.

4.We will provide lifelong technical support started from using of the machine.

5.We will supply normal parts within warranty period to ensure better user experience. Parts supply will be charged after warranty period.

Any further questions please contact with us.

Best regards,

Jenny Yang