Weston WSTQF-1080 Automatic Paper Box Cup Tags Label Waste Stripping Machine

Quotation

| QUOTATION | |||

| Model | |||

| QTY | |||

| Price | |||

| Payment | L/C, T/T | ||

| Port | Ningbo | ||

| Remarks: 1. 30% for deposit,70% before delivery. 2. The quotation is valid for 2 months. | |||

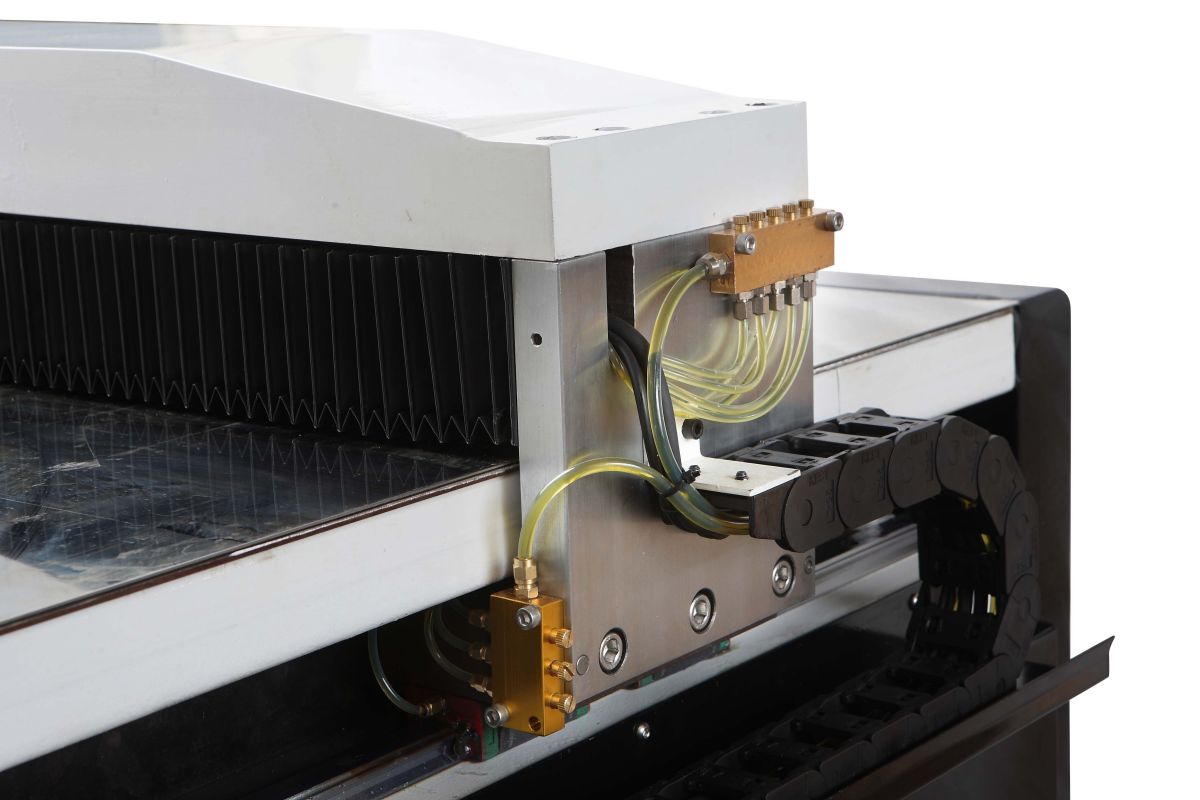

Centralized lubrication system

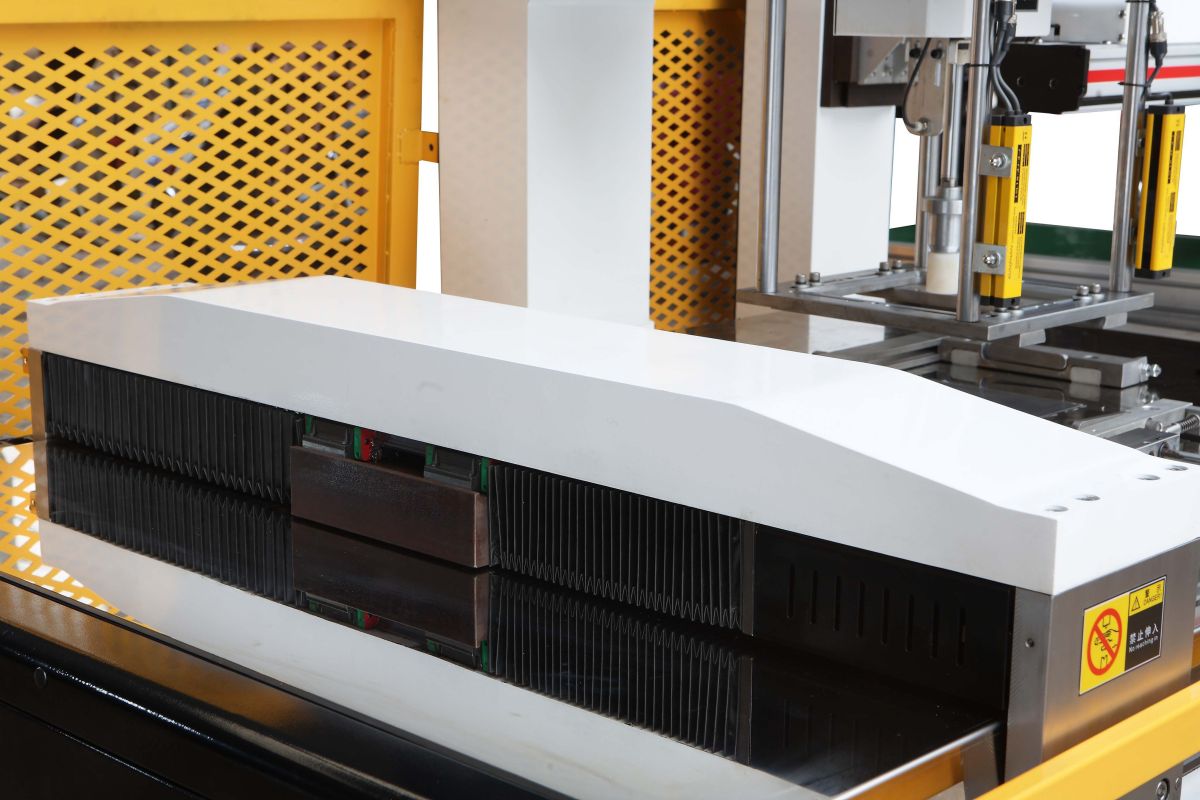

Paper gauge with hidden motor and ball screw

Adjustable hydraulic system

Safety fence

Performance and use

1.Compraring to traditional stripping machine which uses gantry frame as the base for installing the stripping mould, our new design adopts one-side independent standing base for installing the stripping mould; this design is space saving, and convinient for operating.

2.Hidden type servo motor and ball screw ensures a precise pile positioning.

3.Adjustable hydraulic system provides adjustable pressure for processing of different materials of different sizes and weights.

4.Stripping needles (rods) are quick and easy to chang to fit differnent products fromats and patterns.

5.Automatci lubricating system carries out regular lubrication, which greatlty extend the service life of the machine.

6.The operation panel adopts visual button to avoid safety accident caused by wrong operation. Its also easy and quick to program at the touch screen.

7.Safety fence at operation side protects the safety of personnel when the machine is running.

technical parameters

| Electric configuration | |||

| Item | Model | Brand | Brand origin |

| DC power supply | NES-100-24 | Schneider | French |

| Relay | RXM2AB2BD(DC240V) | Schneider | French |

| AC contactor | LC1-0910 | Schneider | French |

| Thermal overload relay | 3UA59(6.3-10A) | Schneider | French |

| Button | XB2BA11C | Schneider | French |

| 4-position switch | XD2PA24CR | Schneider | French |

| Knob | XB2BD2C | Schneider | French |

| proximity switch | XS212BLNBL2C | Schneider | French |

| Servo motor | F-H08AF2 | Evta | China |

| Thermal overload relay | 3UA5240-1K | Siemens | Germany |

| Leakage protection airswitch of general power supply | BKN-D16-3 | GL | South Korea |

| Leakage protection airswitch of independent power supply | BKN-D6-1 | GL | South Korea |

| Touch screen | 10.4'' | Weinview | Taiwan |

| Micro-computerized controller | AFPXHC40-F | Panasonic | Japan |

| Machine technical parametrs | |

| Model | WSTQF-1080 |

| Max sheet size (X) mm | 1080 |

| Max sheet size (Z) mm | 780 |

| Min sheet size (X) mm | 650 |

| Min sheet size (Z) mm | 450 |

| Max pile height mm | 100 |

| Min pile height mm | 40 |

| Work table height mm | 850 |

| Max product size to be punched out | 450*450 |

| Min. product size to be punched out | 30*30 |

| Stripping speed times/min | 15-22 |

| Max. force (bar) | 70 |

| Manipulator arm technical parameters | |

| Model | WSTQF-1400 (for 1080R) |

| Trip | 1400 mm |

| Clamping range | 30-180 mm |

| Clamping weight | 50 -1500 g |

| Empty running speed | 5-50 m/minute |

| Air source | 4-7 bar |

| Air consumption | 1 L/min |

| Power supply voltage | 220V, 50HZ |

| Power consumption | 0.4KW |

| Net weight | 200 kg |

| Rotating mould technical parameters | |

| Model | WSTQF-1080T |

| Trip | 0-180 degrees |

| Rotating speed | 10-80 degree/second |

| Air consumption | 1 L/min |

| Air source | 4-7 bar |

| Power supply voltage | 220V, 50HZ |

| Power consumption | 0.75KW |

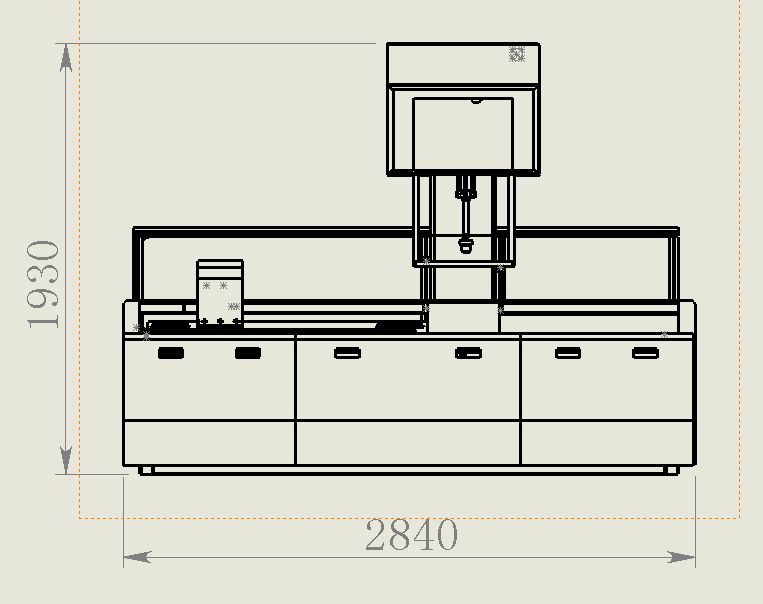

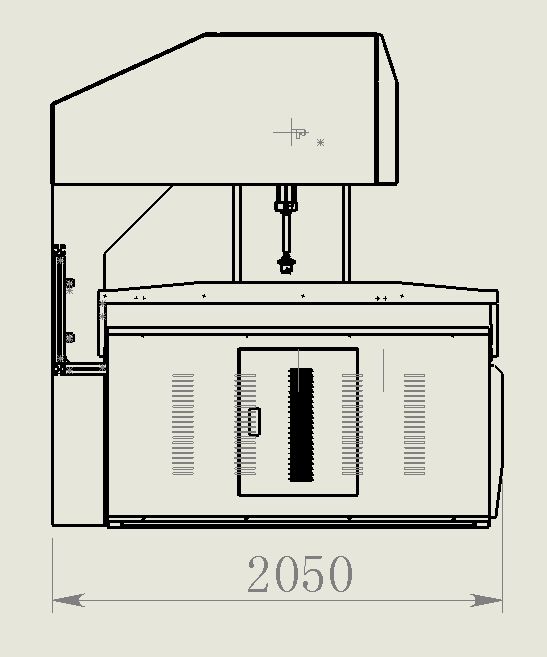

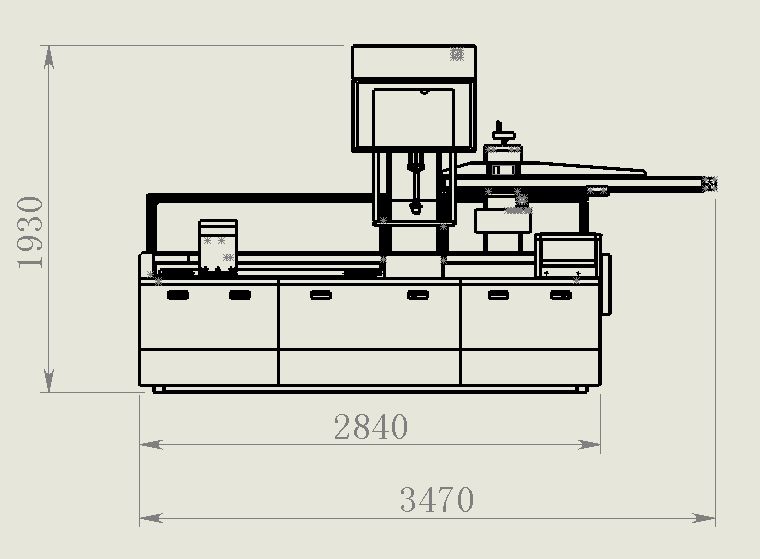

| Machine installation data | |

| Model | WSTQF-1080 |

| Machine width mm | 2840 |

| Machine depth mm | 2050 |

| Machine height mm | 1930 |

| Net weight kg | 2000 |

| Air source Bar | 4-7 |

| Air consumption L/min | 2 |

| Power supply voltage | 360V-420V,50/60HZ |

| Power consumption A | 2 |

| Insurance current A | 10 |

| Input power | 3hPE |

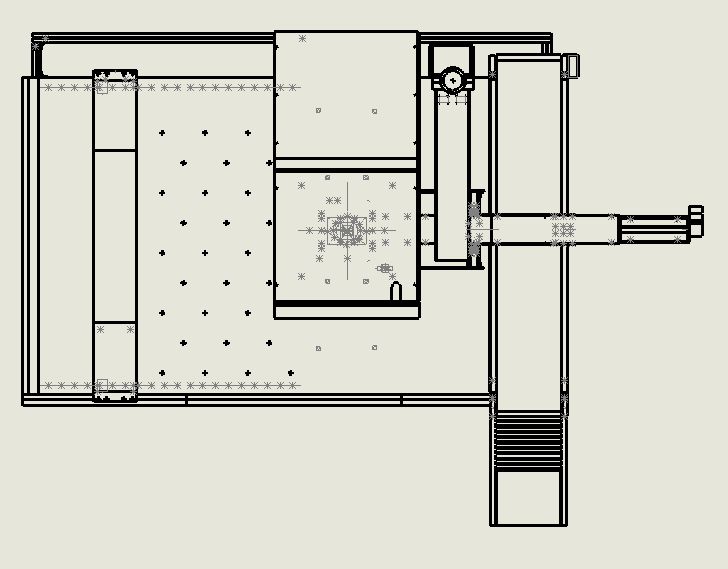

Three view dimension drawing of WSTQF-1080

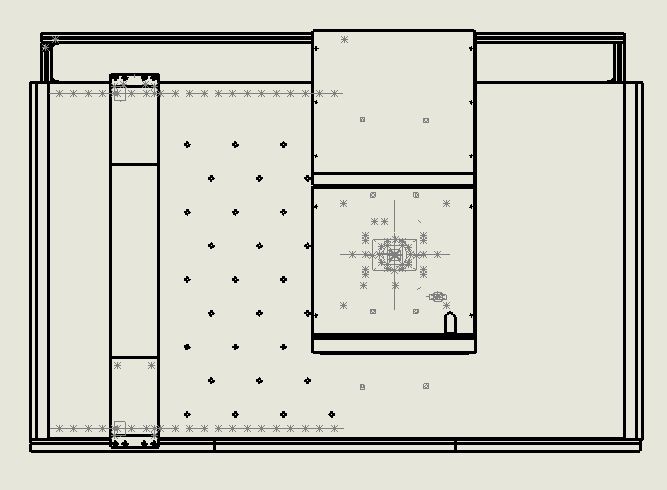

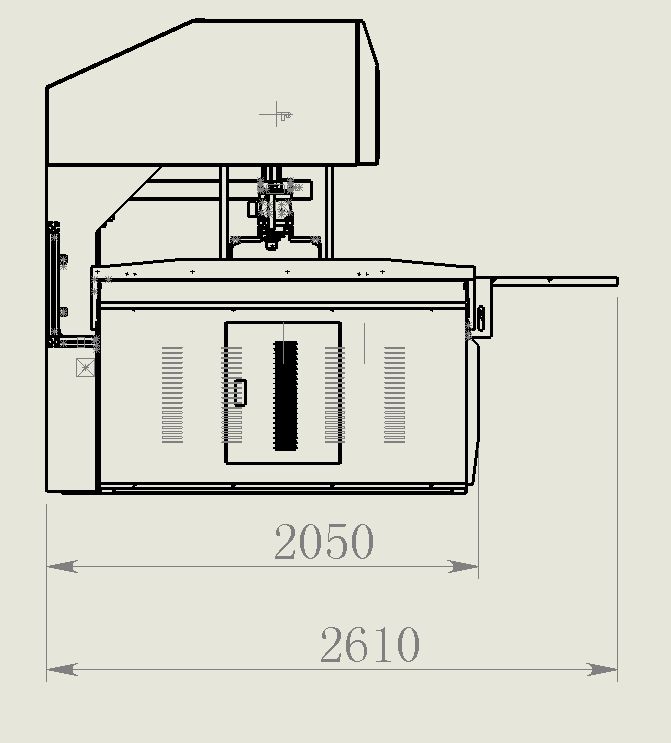

| Machine installation data | |

| Model | WSTQF-1080R |

| Machine width mm | 3470 |

| Machine depth mm | 2610 |

| Machine height mm | 1930 |

| Net weight kg | 2200 |

| Air source Bar | 4-7 |

| Air consumption L/min | 3 |

| Power supply voltage | 360V-420V,50/60HZ |

| Power consumption A | 2.4 |

| Insurance current A | 10 |

| Input power | 3hPE |

Three view dimension drawing of WSTQF-1080R (Including manipulator arm)

| Tool cabinet | |

| Name: | Quantity: |

| Tape measure | 1 |

| Push head | 1 |

| Slotted screwdriver | 1 |

| Cross screwdriver | 1 |

| Screws and nuts | Many |

| Sponges | Many |

| Adjustable wrench | 1 |

| Thimble mould | A set |

| Pressure plate | 14 |

| Inner hexagon spanner | A set |

| Open end wrench | 1 |

Our service

You can expect satisfactory customer service with long tradition. We are highly devoted to the most optimal solid and liquid separation solutions to meet your specific needs. We have the effective service system to ensure professional and flexible management of any affairs.

1.Pre-sales technical consultation

2.Model selection

3.Machine guidance

4.Operation & maintenance training

5.Maintenance service

6.Quick supply of spare parts

7.Customer satisfaction track

After-sale Service

We promises that all machines made by us come with services of repair and replacement.

Machine warranty is 12 months. We provide free repair services to any failures caused by us within warranty time. However wearing parts are not included.

1.Any quality failure problems happens within guarantee period, we will reply within 4 hours after receiving your request.

2.We will provide lifelong maintenance service to all parts and regular maintenance to flatbed die cutters.

3.We will handle any quality failure occurred within warranty time.

4.We will provide lifelong technical support started from using of the machine.

5.We will supply normal parts within warranty period to ensure better user experience. Parts supply will be charged after warranty period.